Engine Management Systems

They are the heart of the car, the various sensors and pumps that control the ignition, fuel and air supply of the engine. It is a vital part of power output and fuel consumption.

Products

Air Flow Sensor

An Air Flow Sensor is a sensor installed in the intake system of the electronic control system to measure the volume of passing air flow (volume of the air taken into the engine).

The air taken into the engine is introduced to the Air Flow Sensor through an air cleaner to measure the volume and temperature of the air and the information is transmitted to an ECU (engine control unit). After the Air Flow Sensor the air passes through an electronic control throttle and taken into combustion chambers.

If the engine lamp comes on after the airflow sensor has been replaced, operability of the vehicle will not be affected, so ask your dealer or a technician to execute a relearning of the ECM to turn off the light.

Product information video: https://youtu.be/DdyU6mq8D7Y

Regional Product Pages

EMEA region:

Americas region:

APAC region:

India:

Alternator

An Alternator is a generator to supply electric power to various control devices and to charge the battery.

An Alternator is an AC generator driven by the engine using a belt. Generated AC electric power is converted (rectified) to DC current using built-in diodes. It supplies electric power to various control devices and charges the battery.

Since the voltage generated by an Alternator has the characteristics to be proportional to the Alternator speed, it is controlled to the defined voltage using a regulator to maintain constant level while the engine speed changes from low to high and vice versa.

In addition some systems adopt charge control for the improvement of fuel economy.

Regional Product Pages

EMEA region:

Americas region:

Camshaft & Crankshaft Position Sensors

A Crankshaft Sensor or a Camshaft Sensor is a sensor to detect the rotation of a crank or a cam shaft respectively.

A Crankshaft Sensor detects the reference position and the rotation angle of a crank shaft and the engine speed.

A Camshaft Sensor is used to determine each cylinder providing a signal to determine the cylinder.

The Camshaft sensor is used to distinguish between the individual cylinders. A gear is attached to the camshaft to identify each cylinder, and a sensor detects the distance to the gear projection.

A Crankshaft Sensor or a Camshaft Sensor receives changing magnetic flux due to the rotation of a rotor having a projection. It converts the flux change to a rectangular pulse signal and send it to ECU.

Regional Product Pages

EMEA region:

Americas region:

APAC region:

India:

Electronic Throttle Body (ETB)

An Electronic Throttle Body is a device to control the flow rate of the air taken into an engine.

With an Electronic Throttle Body the depression amount of an accelerator pedal is converted to an electric signal and ECM (Engine Control Module) controls the DC motor to open or close the valve.

It is possible with an Electronic Throttle Body to open or close the throttle valve in responding to the operating condition of the vehicle. Compared to a mechanical type throttle chamber, ETB has higher preciseness and accuracy of throttle valve opening control and plays an important role to improve the fuel economy.

Relearning is required after replacement of the ETB in accordance with the instructions to ensure adequate performance.

Product information video: https://youtu.be/7z5NhJqWm0M

Regional Product Pages

EMEA region:

Americas region:

Fuel Injector

It is a device to inject the fuel supplied from a fuel pump to the cylinders.

A fuel injector is an actuator installed to an intake manifold of an engine and injects the fuel supplied by a fuel pump. The injected fuel is mixed with the intake air and introduced into the cylinders to generateengine output through combustion process.

Regional Product Pages

EMEA region:

Americas region:

Fuel Pump

It is a device to draw fuel from a fuel tank and to deliver it to injectors.

In the early stages of electronic fuel injection systems, fuel pumps were out-of tank, in-line type which installed outside of the fuel tank. From about 40 years ago in-tank type pump which installed inside of the tank became the mainstream.

Currently module type that integrates not only a pump but also a fuel flow rate detection device as a potentiometer or a float arm, a fuel filter and even a pressure regulator that regulates the fuel pressure is the mainstream.

Regional Product Pages

EMEA region:

Americas region:

APAC region:

India:

Idle Speed Control Valve

An Idle Speed Control Valve is a device to supply auxiliary air to the air intake pipe bypassing a throttle valve.

It stabilizes the engine speed at idle by adjusting the amount of incoming air after the engine has started. Also, it stabilizes the engine speed in response to electrical loads such as air conditioning.

Regional Product Pages

EMEA region:

Americas region:

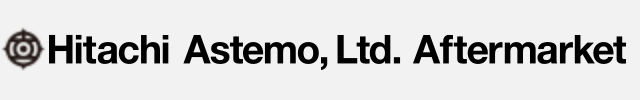

Ignition Coil

An ignition coil is a device that transforms the 12-volt current from battery into the high-volage current.

An Ignition Coil is composed of a primary coil and a secondary coil which have different number of turns. When the current to the primary coil is cut off, high voltage is generated to the secondary coil by electromagnetic induction. In the past, high voltage generated at the Ignition Coil was distributed to SparkDistributer. In these days, Direct Ignition type which has no Distributer became main stream. Since this type uses an Ignition Coil at the top of Spark Plug of each cylinder, it is called as plug top type as well.

Plugs of each cylinder through a The ignition coil consists of a primary coil and a secondary coil, each with a different number of wire turns. The primary coil generates a magnetic field with the battery voltage and by using this magnetic field; the secondary coil will have tens of thousands of volts of induced current.

Hitachi is the first in the world to start mass production of the Plug Top Coil in 1985. Today the Plug Top Coil is the most standardized due to ease of modification for changing OE demands and battery durability.

We recommend to replace an ignition coil when you find the symptoms such as engine misfires, rough idle, or loss of power.

When you replace the bad ignition coils, we recommend to replace all ignition coils at once.

Product information video: https://youtu.be/b_VKAkc1ho0

Regional Product Pages

EMEA region:

Americas region:

APAC region:

India:

Starter Motor

It is a driving device to start the engine using the power of a motor.

An automobile engine can not be started by itself, it must be driven by an external force to turn the engine to a speed at which it can be started. this driving device is the "Starter Motor". The Starter Motor has to generate a very large torque since the starter motor has to drive the crank shaft to the speed that able to start the engine using only the power supply from the battery and by mating the starter pinion gear with the ring gear on the peripheral of the engine flywheel. In the past, pinion sliding type was used mainly but now, reduction type is the main stream. Reduction type motor transmits the rotational power to the pinion gear via a reduction gear, in order to increase the rotating torque while reducing the size and weight.

Regional Product Pages

EMEA region:

Americas region:

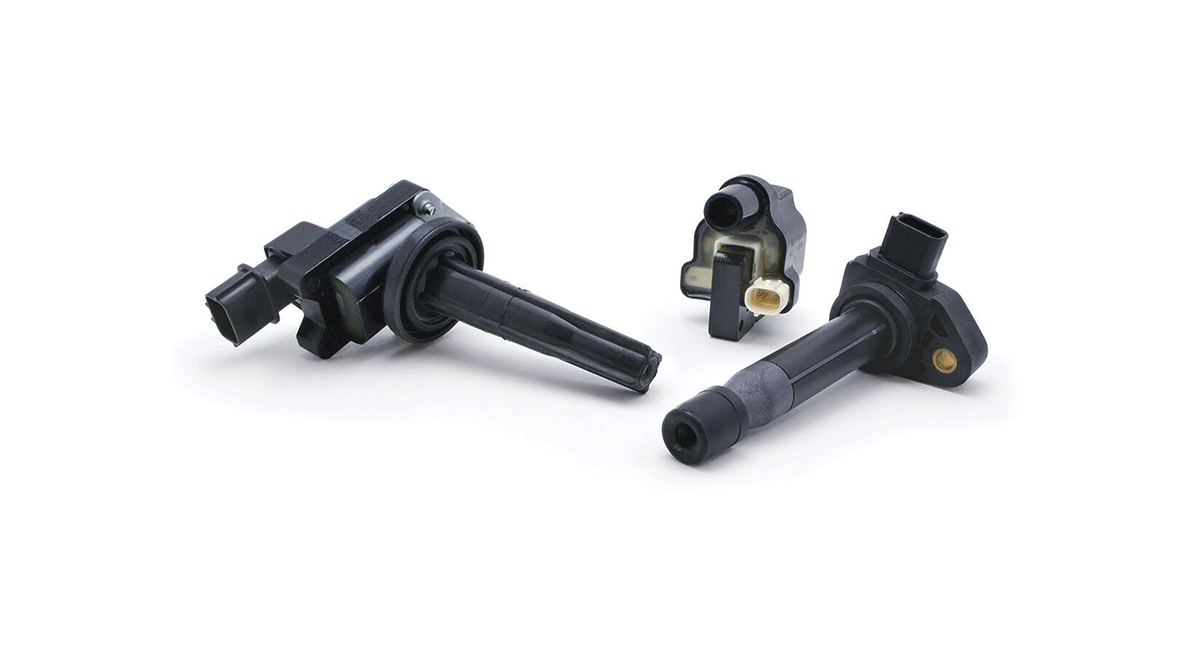

Turbocharger

Turbocharger drives turbine by exhaust gas from engine.

Compressor, which integrated with turbine, compresses air and supplies air to engine.That is turbocharger can supply large air to engine by exhaust gas energy.

Turbocharger takes advantages for output improvement and against exhaust gas measure.

O2 Sensor

O2 Sensor detects concentration of residual oxygen in exhaust emission.

It is being installed in front and behind of catalyzer.

Regional Product Pages

EMEA region:

Sensors

help your car's ECU monitor vital parameters such as Air Intake Temperature, Camshaft/Crankshaft Position, Knock Sensor, Crankshaft Angle, Pressure Sensor, Throttle Position.

With modern automobiles replying more and more in computers (ECU) to more efficiently control the cars functions, sensors have become vital to your car running efficiently. Hitachi's sensor line supports accurate measurement for reliable engine performance. Accurate measurements ensure your car is running efficiently which optimizes fuel economy and performance.

Regional Product Pages

EMEA region:

Americas region:

APAC region:

India:

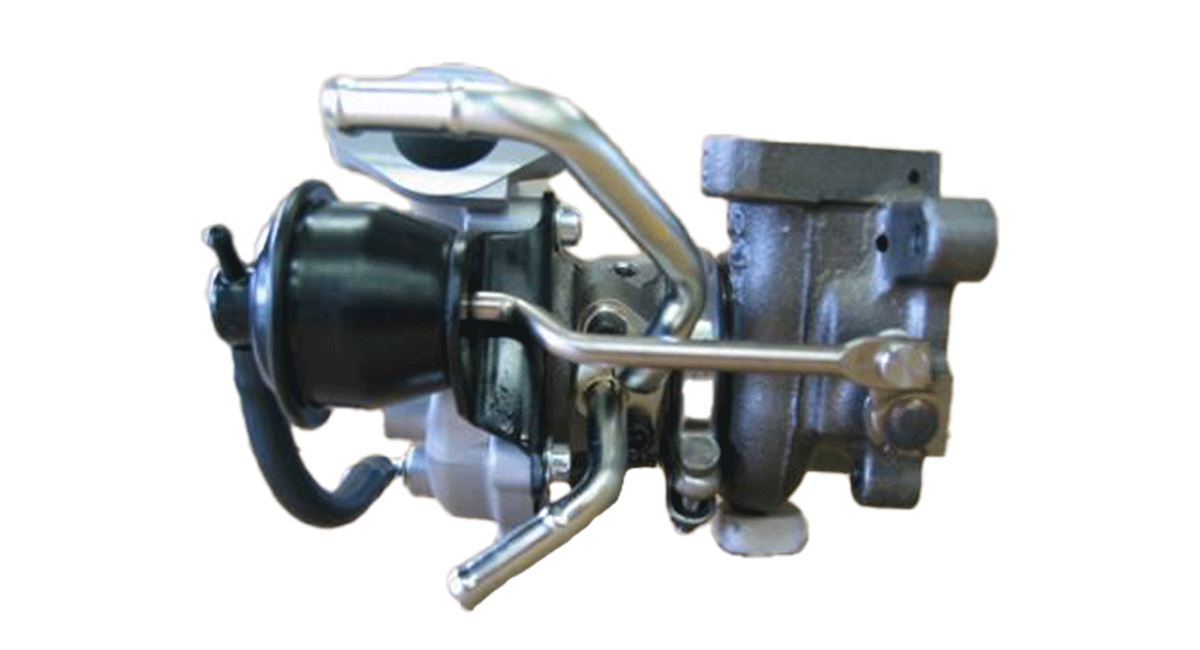

Oil Pump

The oil pump supplies the oil needed to lubricate and cool the engine to each part of the engine.

The oil pumps are vital to protecting engine components from frictional wear and overheating. Hitachi Astemo oil pumps ensure sufficient lubrication and smooth oil circulation. Oil lubricates moving engine parts to allow them to operate smoothly with less resistance and friction. A well lubricated engine increases the odds of a longer service life from its parts. The oil pump also helps disperse engine heat by providing a steady flow of oil and lubricating metal engine parts as they work and carrying heat away from the combustion area.

Regional Product Pages

Americas region:

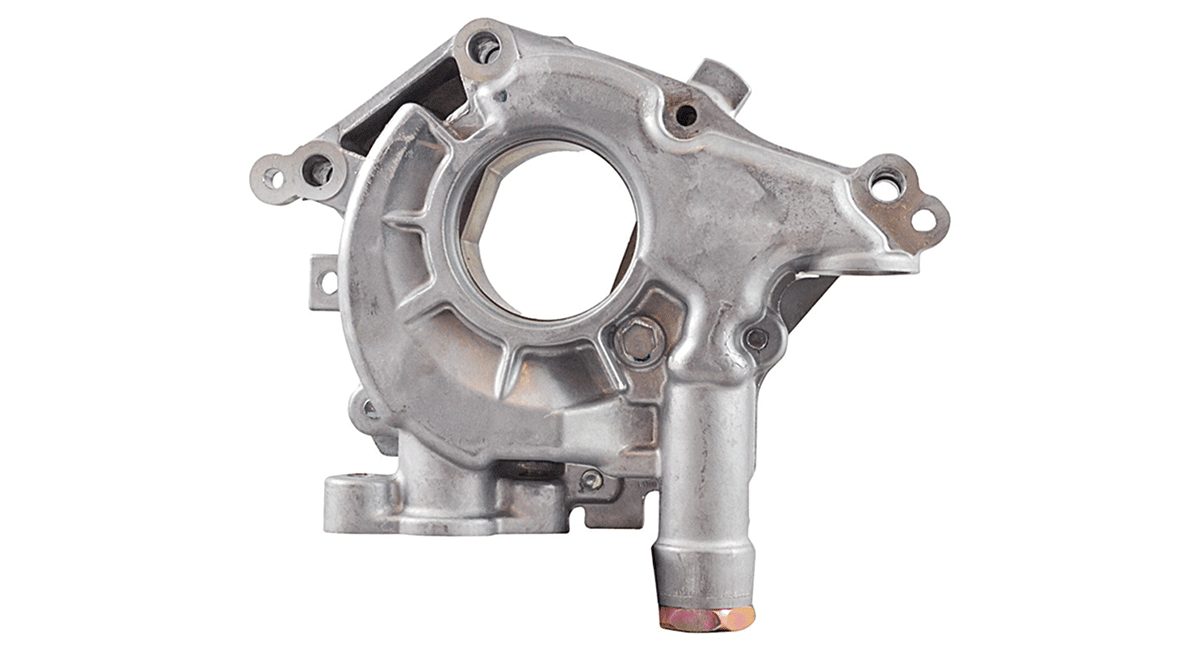

Water Pump

Water Pump is the device to circulate coolant around engine.

Cooling the area around the cylinders is critical to the life of your engine.

Our water pump delivers the crucial element to maintain the engine's temperature and prevent overheating by pumping coolant throughout the vehicle's cooling system to keep things at the right temperature as the heart of the cooling system

Regional Product Pages

Americas region:

High Pressure Pumps

The high pressure pump is specially designed to improve charging efficiency and anti-knock performance by injecting gasoline directly into the cylinder. It compresses fuel to a high pressure and supplies it to the injector according to the demands of the electronic control unit. The flow control solenoid valve has a unique structure and is used to achieve both industry-leading quietness and a large flow rate. In addition, we have achieved the smallest height in the industry through a unique internal configuration, resulting in a superior design for mounting.

Regional Product Pages

EMEA region:

Americas region:

APAC region:

India: