Chassis Systems

It is an essential device for the running of the car. It determines the safety and driving performance of the car.

Products

Shock absorbers & Struts

The strut is an integral product that contributes to the vehicle's performance, not only improving ride quality but also controlling the stability of the vehicle. Inspection and replacement of this part are recommended if the vehicle's movement feels spongy or abnormal noise is coming from the vehicle while driving.

We provide a safe and high-quality Twin-tube shock absorber, Coil-over type shock, strut cartridge and strut assembly. Hitachi Astemo is a manufacturer with ISO standards.

Strut is an integral part of the suspension. Which integrates numerous different suspension parts into one compact assembly. It supports the weight of the vehicle and helps adapt to road irregularities. Our shock consists of a piston in a sealed tube filled with gas and/or liquid. When a vehicle hit a bump, the shock is meant to allow the wheels to absorb the bump and recover.

Replacement of this part, including the rubber boot, is recommended if abnormal noise, rattling, jolting, sponginess, instability, etc. are detected. If the boot is found to be cracked or broken, leaking oil, or bent, it could be dangerous to keep driving the vehicle, so it is recommended that the part be replaced immediately. Regular replacement is recommended at around every 30,000 km.

Brand: TOKICO, SHOWA

Product information video: https://youtu.be/-EmtFTdguqw

Regional Product Pages

EMEA region:

Americas region:

APAC region:

India:

Catalogue Download Page

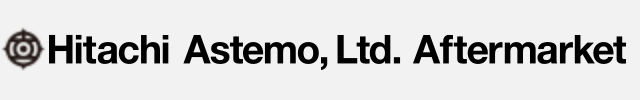

Air Compressor for Air Suspension

An air compressor is a component that pumps air to an air spring or air tank to maintain and pressurize the air pressure inside the air spring for Air suspension.

Brand: HITACHI, HÜCO

Regional Product Pages

EMEA region:

Americas region:

Hydraulic power steering gear

The hydraulic power steering system is a system mechanism that uses the engine's output to provide power assistance to the steering wheel's steering force. The part that generates the force to turn the tires is the hydraulic power steering gear.

The operating principle is the steering control assist by making a hydraulic pressure from the power steering pump (oil pump) with the engine revolution through the V-Belt, and sending the hydraulic pressure to a cylinder to move the inner piston which is in a power steering gearbox.

The power steering pump uses the engine output more than the required flow rate when the car moves because it is driven by the engine. To resolve this problem, a variable displacement pump has been developed which is able to change the discharge flow rate according to the engine speed and discharge the required flow rate, this type satisfies both the fuel efficiency and the steering performance.

Malfunction, oil leakage, or a cracked boot may cause failure while driving, so early replacement is recommended.

Brand: HITACHI

Regional Product Pages

Americas region:

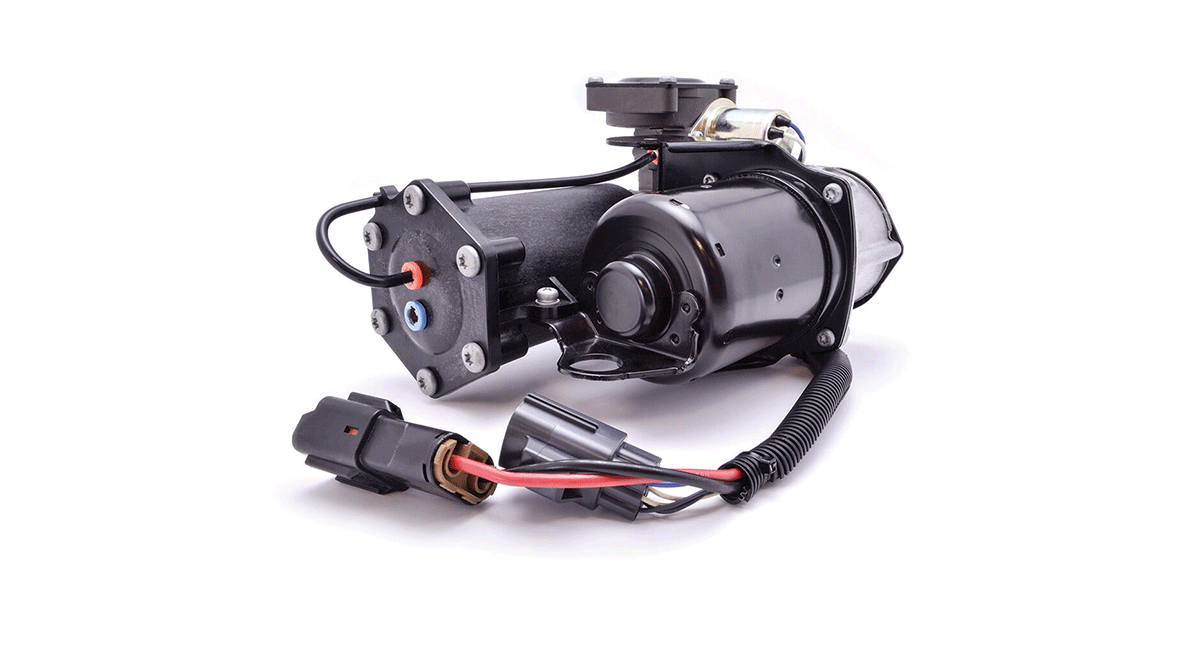

Hydraulic power steering pumps

The Hydraulic power steering pump is a mechanism to assist the steering force of the steering wheel. The hydraulic power steering pump uses the engine output to generate oil pressure. Its structure achieves both fuel economy and steering performance. Early replacement is recommended in the event of oil leakage or abnormal noise.

Brand: HITACHI, HÜCO

Regional Product Pages

EMEA region:

Americas region:

APAC region:

India:

Tie Rods (TRE/TRI)

The tie rod end connects the steering gearbox and the steering knuckle. This is an important part that transmits steering force to wheels and tires.

The tie rod end consists of shaft, ball joint, and dust boot. The ball joint, an important part of the tie rod end, comprises a ball stud and nylon bearing, which achieves both high operability and durability.

The rubber boot that covers the ball joint provides high durability and dust resistance for long periods of time.

A cracked boot will adversely affect the operability of the ball and may cause damage, so early replacement is recommended if a crack is detected. Regular replacement is also recommended.

Brand: HITACHI (North America)

Regional Product Pages

Americas region:

Disc Pad

Brake Pad is to generate breaking power by squeezing a revolving rotor which combines with a wheel. "Explanation of the principles of brake operation and the function of the brake pads When the brake pedal is depressed, hydraulic pressure is generated in the master cylinder, and the piston, which is a component of the caliper, is pushed out by the hydraulic pressure. This causes the pads to sandwich the rotating rotor, and braking force is generated by the frictional force of the pads and rotor.

Brake pads are composed of steel backing plates and friction material. The friction material is designed to perform friction force and durability in line with the characteristics of each vehicle by combining around 20 different materials.

The brake pads must be inspected, serviced, and replaced immediately if abnormal wear, abnormal noise, judder, or insufficient braking is detected.

Be sure to wipe off any grease or other oil on the surface of the pads (contact surface between pad and rotor). Replacement is recommended when the brake pad thickness reaches 4 mm or less.

Brand: HITACHI, TOKICO

Product information video: https://youtu.be/MUNoSRbzJaA

Regional Product Pages

APAC region:

India:

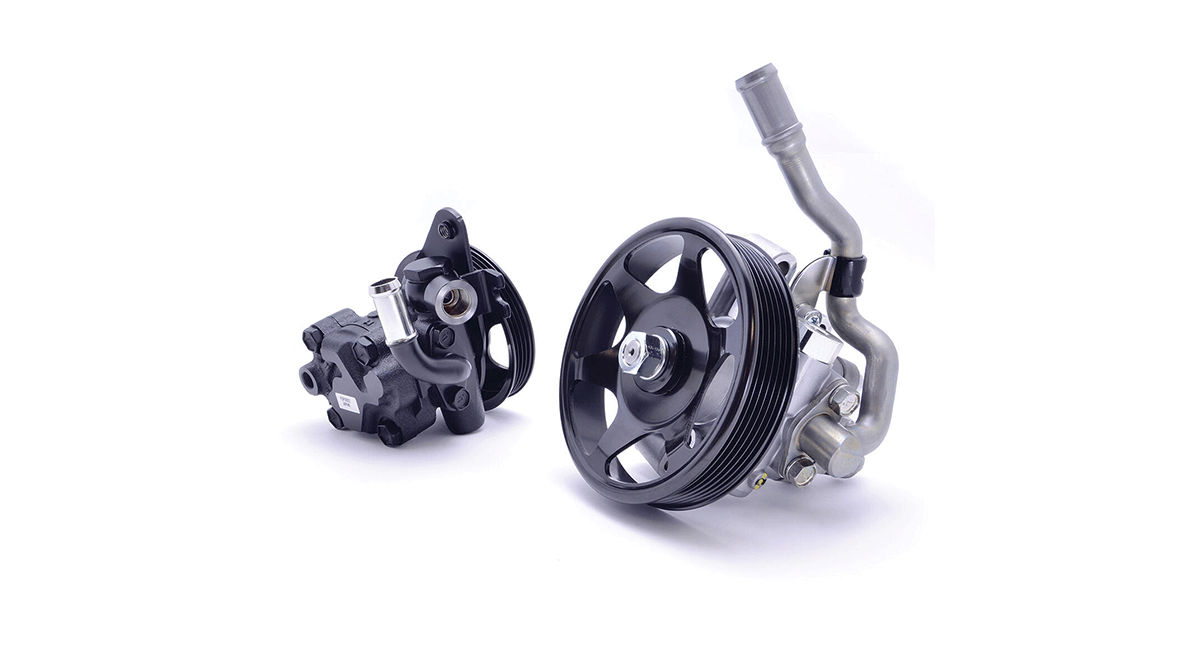

Brake Rotor

The brake rotor is attached to the vehicle via a hub and rotates in the direction of travel of the vehicle.

When the brake pedal is depressed, the brake pads sandwich the brake rotor from both sides, and the braking force is generated by the frictional force thus generated.

The brake rotor rotates together with the tires and wheels. To slow down or stop the vehicle, the brake pads sandwich the brake rotor to generate frictional force and compress the rotor to generate braking force.

Explanation of the principles of brake operation and the function of the brake rotor:

When the brake pedal is depressed, hydraulic pressure is generated in the master cylinder, and the piston, which is a component of the caliper, is pushed out by the hydraulic pressure.

This causes the pads to sandwich the rotating rotor, and braking force is generated by the frictional force of the pads and rotor.

Brake rotors are mainly made of cast iron and are designed and manufactured using a great deal of know-how about factors such as thickness, size (diameter), material composition and cooling performance. This ensures proper braking performance and durability of the vehicle.

The brake rotor must be inspected, serviced, and replaced immediately if abnormal wear, abnormal noise, judder, or insufficient braking is detected.

Be sure to wipe off any grease or other oil on the surface of the pads (contact surface between pad and rotor).

Replace the rotor immediately if cracks, strains, splits, or wear limits are visibly detected.

Brand: HITACHI, TOKICO, NISSIN

Product information video: https://youtu.be/wvItKkk-sMU

Regional Product Pages

India:

Aluminum Wheel

The functions of the wheels are to support the weight of the vehicle via the suspension and transmit the rotational force (the driving force of the engine) of the axle (drive shaft) to the tires.

Aluminium wheels are lightweight and enhance the motion of the suspension. They also improve handling and braking performance, as well as riding comfort, which provides better driving performance.

HITACHI Astemo's aluminium wheels are produced at an Indonesian plant that produces more than 1 million wheels annually. 90% of those wheels are exported to Europe and America. Our aluminium wheels have been tested and certified to international safety standards.

This is a cast aluminium product.

Inspection and replacement are recommended in the event of driving or an accident in which the tire or wheel is hit hard enough to cause air leaks, cracks, or other damage.

Countries of Sale: Europe, US, Indonesia

Brand: TORSION

Learn more (https://www.chemco.co.id/)